vertical pressure leaf filter

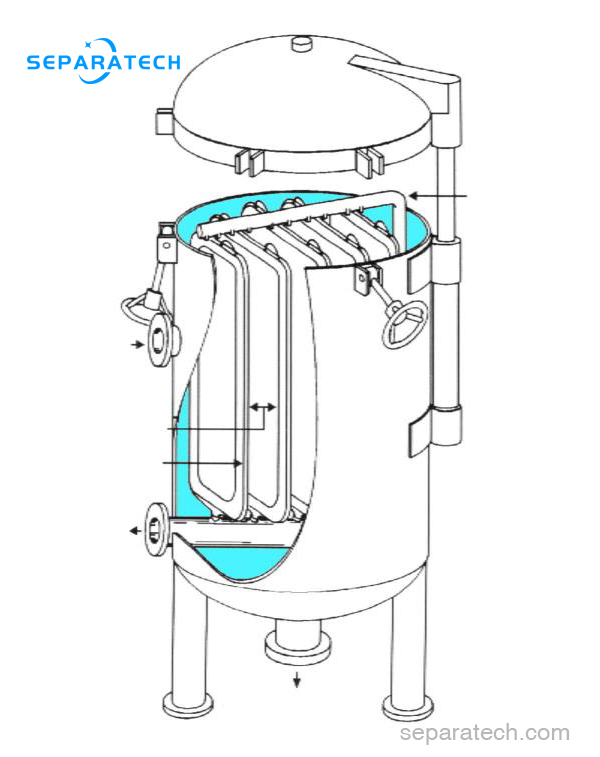

Vertical pressure leaf filter is liquid filtration system consisting of many leaf-shaped filter elements that are stacked inside a vertical vessel.

Vertical pressure leaf filter has been specifically designed to provide a large filtration area which is made possible due to the shape of their filter leaf elements. These vertical pressure leaf filter systems produce high filtrate clarity after the clarification run. Different types of filter aids can be used in vertical pressure leaf filters to improve filtrate quality.

Advantage of vertical pressure leaf filter

= Filtration rates are 2-3 times higher on same filter area of plate & frame filter.

= Stainless steel filter elements, hence no repetitive cost, washing and maintenance of filter cloth.

= Automatic cake discharge in very short time without opening the filter from top, hence large saving in labor and time.

= Very low % of unfiltered liquid retention in cake.

= Closed & pressurized operating system hence no spillage & loss of liquid, which helps in handling volatile / inflammable liquids & clean working environment. Entire filtration cycle with cake discharge can be completed without even opening the filter from top.

= Compact & light hence large saving in floor area & supporting structures.

= Pressure leaf filter can be completely automated with no human intervention.

= Vertical pressure leaf filter can be used for getting filtered liquids as well as cake.

Vertical pressure leaf filter working principle

Leaf Filters are ideal for solid-liquid separation & work on principle of precoating & pressure.

Pre-coating is done with the help of suitable filter aid about 0.5 to 1% (Bleaching earth, supercel, hyflo, superflo etc.) mixed with the liquid to be filtered. Unfiltered liquid is pumped into the filter vessel. Initially the filter aid starts forming a precoat layer on both sides of the filter leaves, until then cloudy material comes out of the filter. Once the layer is formed, pressure starts developing, restricting the impurities. Clear liquid flows from both sides into the leaves (filter elements), flows along the tubular channel & gets discharged from bottom of the leaf. All the leaves are mounted on a common manifold. The leaves start getting choked on both the sides by impurities forming cake, which is in wet from. Once the leaves get choked completely, the pressure rises to 3 kg/cm2 & the output flow almost stops. This means the batch size is reached. The pump is stopped & steam / air pressure is applied from the top (without dropping the filter pressure) to filter the material around the leaves held up in the tank & to squeeze the cake further & reduce the liquid retention in it. The holdup unfiltered liquid in the conical portion is taken back.

How is the Leaf Constructed ?

Each leaf is made of 5-ply of SS wire mesh of different gauge wires. Two outer filtering mesh and three inner are only for support. Different outer filtering mesh is used for different fitleration process. The 5-ply wire mesh are held together by a tubular frame and made leak proof by machine rivetting. The quality of filtration and life of filter depends mainly on the quality of outer wire mesh and revetting. SEPARATECH ensure the quality by inspecting quality of wire mesh and each leaf. Old worn out and torn leaves can be repaired by only replacing the outer weave. Optionally we also provide cloth on the leaves for fine or special filtration.