Used centrifuges + OEM centrifuge parts

River Decanter Centrifuge for Vegetable Protein and Starch Processing

The decades of experience in the field of centrifugal separation technology for vegetable protein and starch processing, intensive research and development and the related innovative ability of River decanter centrifuge guarantee the company’s customers throughout the world the technical lead which is necessary for successfully operating in global markets. A reliable decanter centrifuge is only really good if it meets all requirements for individual and customer- oriented solutions in the field of process engineering. Decanter centrifuge is widely used for extracting, concentrating, recovering and washing the protein and starch. Potential feedstocks including yellow pea, faba bean, mung bean, chickpea, lentil, soy, lupine, alfalfa, wheat, etc.

In protein production River decanter centrifuges are used for extracting, concentrating and washing the protein. Sophisticated drive systems ensure a high level of dry substance. The special drive developed by River enables the differential speed to be adjusted continuously to suit the protein volume to be separated. Only in this way can maximum dewatering rates be obtained. With the aid of adjustable impeller the decanter’s immersion depth can be adjusted with the machine running. With this system machine down time periods are avoided completely. Trouble-free optimum adjustment of the immersion depth also increases the relative clarifying surface, so that even minute particles are reliably separated out.

A vegetable protein manufacturing process essentially comprises protein extraction, purification, and drying, whether that process is used to make a concentrate or an isolate. The procedure also includes further processing of by-products, such as fibers, starch and soluble components in the water effluent streams. Clean-in-Place (CIP) and automation complete the installation to ensure reliable and hygienic production of vegetable protein ingredients for food and feed applications.

The starting material for protein extraction is often a flour — obtained from beans or seeds by dehulling, grinding and sieving — which is then mixed with water in a predefined ratio to balance cost-effectiveness with protein purity and yield. The pH of the mixture is subsequently adjusted to acid or alkaline, dependent upon the final product that is being manufactured.

Protein concentrate extraction

Liquid extraction of a protein concentrate starts with protein coagulation and separation of the precipitated proteins and insoluble fibers using a River decanter. Coagulation occurs at a pH around the isoelectric point or at elevated temperatures. The collected solid phase is then dried in either a ring dryer or spray dryer, depending on the type of product and the final use of the protein concentrate. This process results in vegetable concentrates with a protein level of at least 50%.

Protein isolate extraction

Protein extraction in lye

In alkaline extraction conditions, the protein fraction dissolves predominantly in the aqueous extract; this is the first step in making a vegetable isolate.

Protein precipitation and purification

The water phase obtained from alkaline extraction contains most of the dissolved proteins; these are subsequently precipitated out of the aqueous phase and separated in a decanter centrifuge. The water phase from the decanter — the whey fraction — mainly consists of salts and soluble carbohydrates.

The solid phase, which remains in the decanter, is known as the protein curd. This undergoes dilution, pH adjustment and thermal treatment before the proteins isolated from the curd are spray dried into the protein isolate powder. Carrying out additional washing in a disc clarifier centrifuge creates an even higher purity of protein isolate.

Starch is obtained predominantly from starch-rich plants such as wheat, potatoes, maize, rice, peas and tapioca. Starch is the material in which plants store reserves of energy, it is a polysaccharide consisting of glucose units. Depending on botanical origin, the starch grains, grain-size distribution and molecular composition of the molecules may vary.

The product that emerges from the extraction process is known as native starch. This is used both in this form and as modified starch, or is processed still further into different kinds of sweeteners and for use in a wide range of fermentation processes.

No matter which particular crop the starch is to be extracted from, the production processes involved are essentially the same. They are all based on making the raw material disintegrate (milling), followed by mechanically separating the different component parts. Cereals such as maize and wheat are milled by grinding whereas tubers/roots such as potatoes and cassava/manioc are shredded using raspers. The subsequent separation of the component elements is carried out either on the basis of their different sizes – using screens or filters – or different weights – using gravitational forces in centrifugal separators (decanter centrifuges, nozzle centrifuges or hydrocyclones).

River decanter centrifuge is used for extracting:

2-phase separation

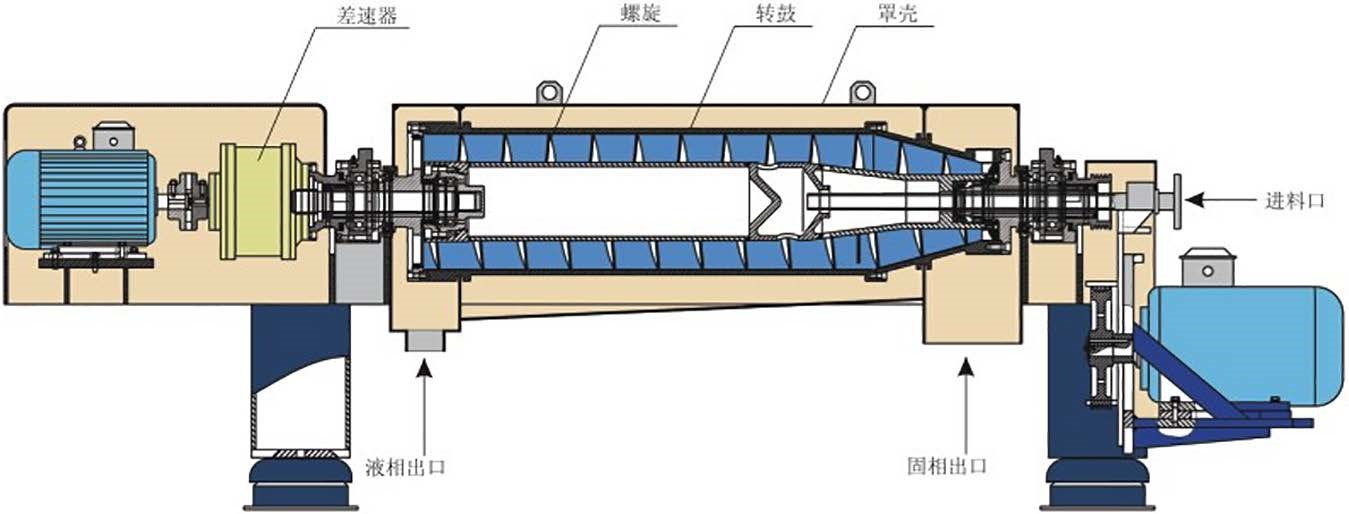

The 2-phase River decanter centrifuge is designed for liquid-solids separation. Separation takes place over the entire length of the cylindrical part of the bowl, which is equipped with a concentric screw conveyor. The product is fed into the bowl through a inlet tube and is smoothly accelerated in the conveyor. Centrifugal forces cause instant sedimentation of the solids on the wall of the bowl. The clarified liquid leaves the bowl by flowing naturally under gravity, over an adjustable weir (overflow dam) and into the casing. Pressurized liquid discharge (using a centripetal pump) is also available, making it possible to transfer the liquid directly without any ambient contact and foam free. The conveyor rotates in the same direction inside the bowl but at a slightly different speed. This difference between bowl and conveyor can be adjusted either manually or automatically. This difference in speed moves the solids to the conical end, where they are lifted out of the liquid. The solids are drained before being discharged out of the machine through the solids outlet.

3-phase separation

The 3-phase River decanter centrifuge is designed for separating raw material into three phases – light liquid, heavy liquid, and solids. The raw material is fed into the bowl through a inlet tube and is then smoothly accelerated. Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. Centrifugal force causes instant sedimentation of the solids on the wall of the bowl. The conveyor rotates in the same direction as the bowl, but at a different speed, and conveys the solids to the conical end.

Because it is lighter, the light liquid flows on the inside, and the solids move towards the outer perimeter, while the heavy liquid remains in the middle. Separation takes place along the entire length of the cylindrical part of the bowl. The two liquid phases discharged into collecting tanks by gravity, or under pressure by centripetal pump.

© 2024 USED CENTRIFUGE - SEPARATECH